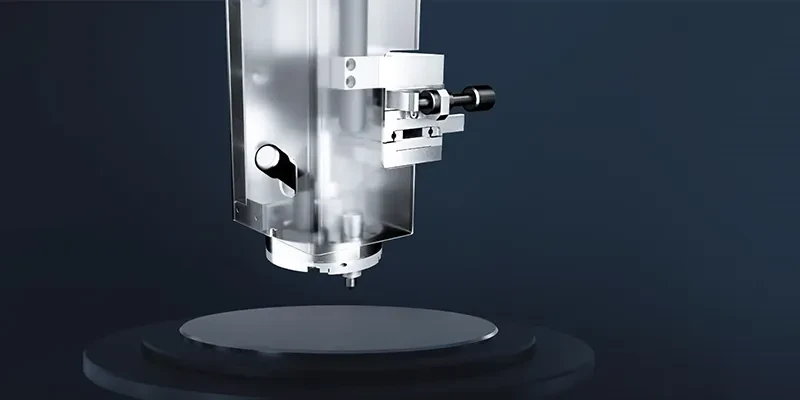

Handheld Laser Cleaning Machine

Your Professional Laser Cleaning Machine Supplier

Skylaser is dedicated to the research and development of laser cleaning. By choosing SKYL, you are opting for a scientific approach to metal surface treatment; by selecting us, you are choosing a comprehensive laser cleaning solution.

Who we are

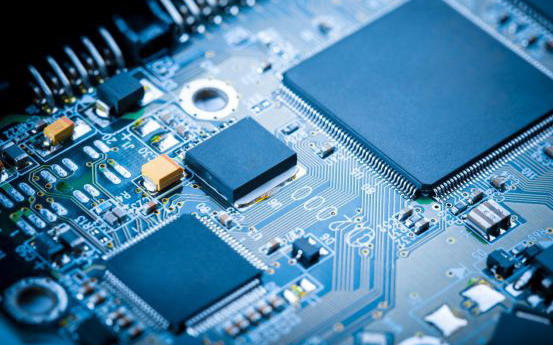

Skylaser is a high-tech enterprise specializing in the research, development, production, sales, and service of laser cleaning equipment. Its headquarter is located in Wuhan, the birthplace of laser technology in China. Relying on the strong scientific research strength of HUST, through more than ten years of exploration and accumulation, Sky Laser has mastered multiple core laser cleaning technologies, independently developed core components and complete machines, and holds over 60 patent protections.

The national standard "Technical Specification for Laser Surface Cleaning in Green Manufacturing" led by our company was officially released in 2022. This filled the gap in current national and industry standards for laser cleaning, and marked a milestone. Skylaser is oriented towards customer needs and user experience, providing customers with high-quality, efficient and comprehensive laser cleaning application solutions as well as all-round pre-slaes, during-sales, and after-sales service.

Our Factory

Skylaser is located in the central city of China - Wuhan. As a global supplier of laser cleaning machines, laser engraving and other laser equipment and components, is committed to creating added value for global customers and growing together.

R&D

The company has a technical team of more than 40 people, involving in laser technology, optical engineering, vision software, embedded hardware, upper computer programming, mechanical design, electrical automation and other fields. At present, the company holds more than 50 industry patents, a number of products and technologies leading the world.

Production Market

We have clients from the Chinese domestic market and the overseas market. Our main sales markets:Asia 65.00%, Europe 15.00%, North America 10.00%, South America 5.00%, others 5.00%.

Our Service

We have a complete remote network technology team, for a variety of laser equipment applications to provide pre-sale, sale, after sale technical support.

- Total 1 page 6 articles