Laser Cleaning Welding Cutting Integrated Machine

Your Professional

Laser Cleaning Machine Supplier

We are a professional laser cleaning machine manufacturer. We Skylaser dedicated to the R&D, production and sales of laser cleaning equipment over ten years. Now we have become one of the major suppliers of laser cleaning industry in China, and led the formulation of China's first national standard for laser cleaning in 2022.

01

High Quality

●Independently developed design.

●More than 50 industry core patents, including more than 20 invention patents.

02

Advanced Equipment

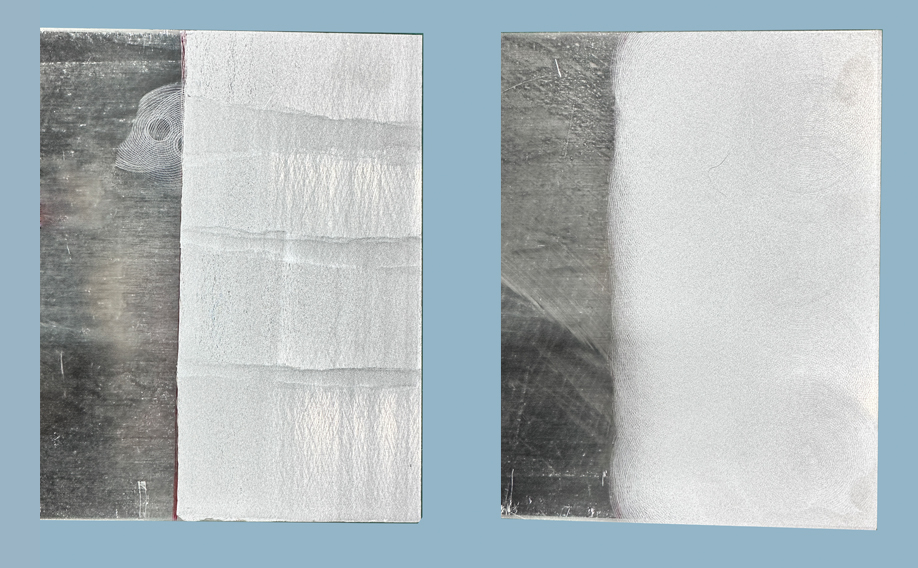

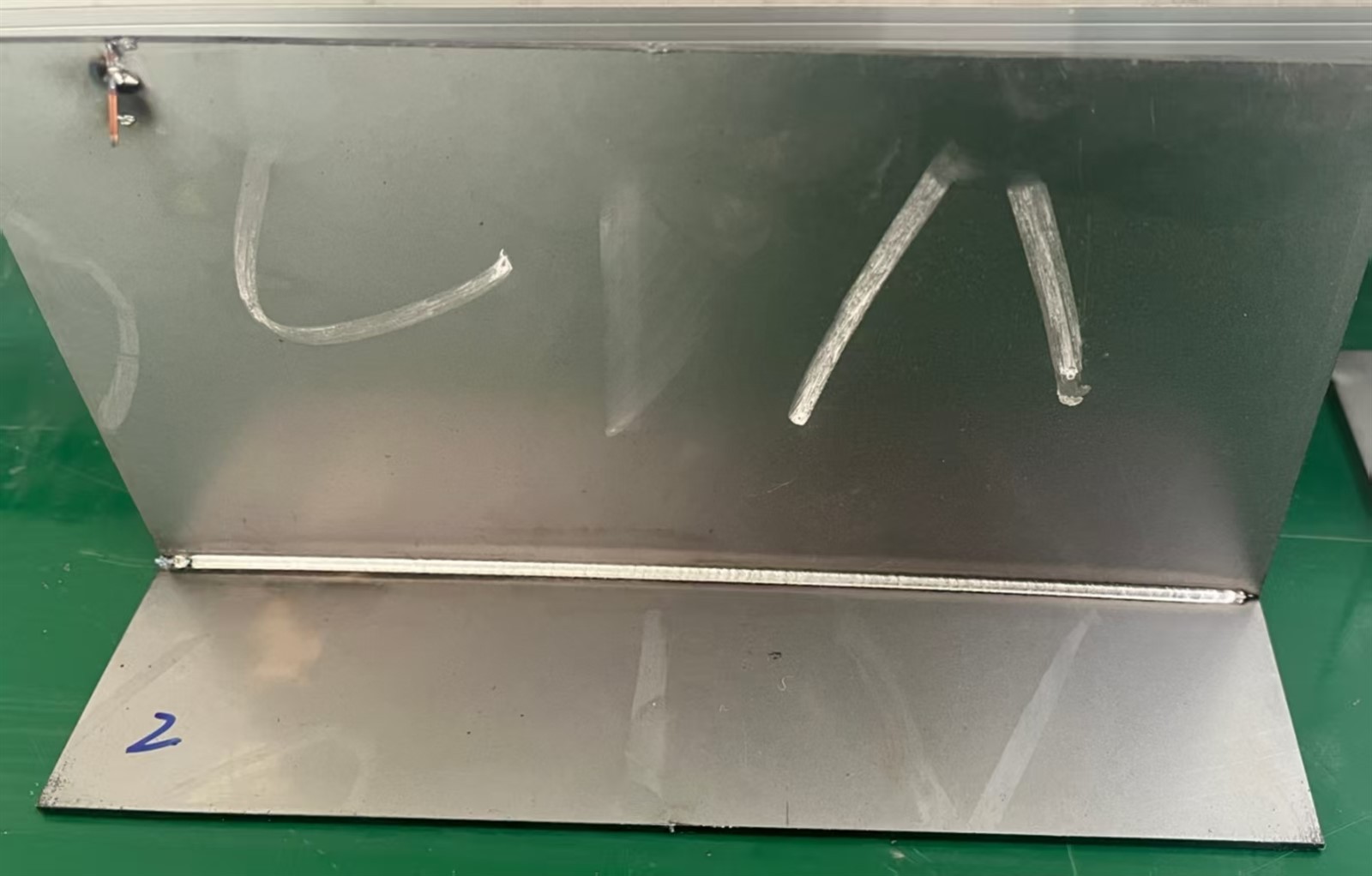

●Established a process database for various substrates and contaminants.

●Safe and environmentally customized light sources.

03

Professional Team

●With the solid scientific research strength of Huazhong University of Science and Technology.

●A R&D team composed of masters and doctors.

04

Custom Service

●Extensive industry application experience.

●A complete remote network technology team can provide pre-sale, sale, after sale technical support.

- Road 1 page 2 strip